Unveiling the Expertise of Metal Fabricators at Deep Mould

Deep Mould stands out as a prominent name in the metal fabrication industry, renowned for its exceptional craftsmanship and unparalleled service. Located at https://www.deepmould.net/, our mission is to provide high-quality metal fabrication services that meet the diverse needs of our clients. This article explores the fascinating world of metal fabrication, the innovative processes we employ, and why Deep Mould should be your top choice for all your metal needs.

Understanding Metal Fabrication

Metal fabrication is the process of transforming raw metal materials into finished products. It involves a variety of steps, including design, cutting, shaping, and assembling of metal parts. At Deep Mould, we specialize in a comprehensive range of fabrication services that cater to various industries, ensuring high standards and precision in every project.

The Metal Fabrication Process

The metal fabrication process encompasses several key stages:

- Design and Engineering: Our journey begins with understanding the client's requirements. Skilled engineers use advanced CAD software to produce precise designs.

- Material Selection: We source high-quality metals, including steel, aluminum, and custom alloys, tailored to the client's specifications.

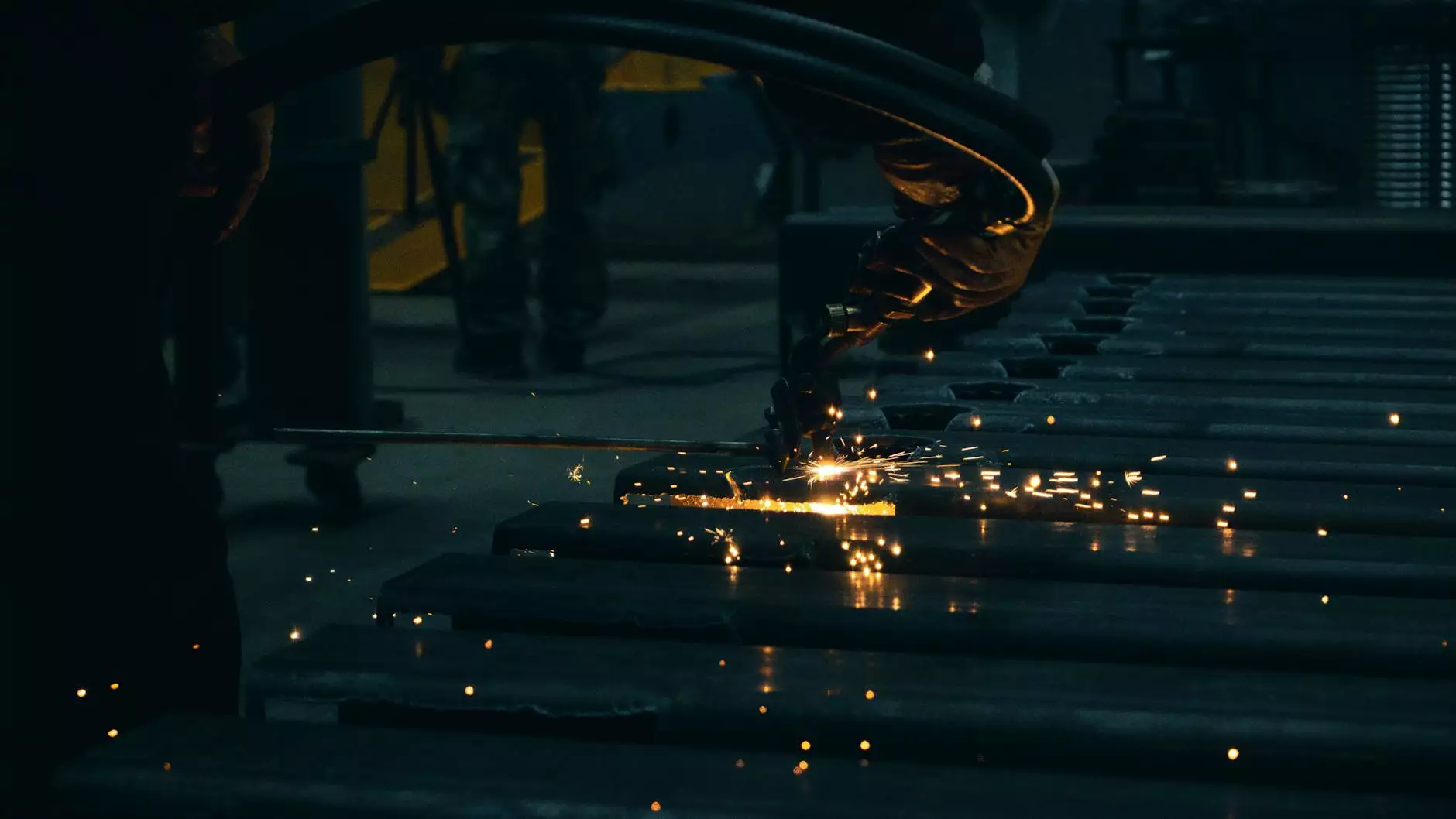

- Cutting: Using state-of-the-art laser cutting and plasma cutting technologies, we achieve exact dimensions without compromising material integrity.

- Shaping: Various methods such as bending, rolling, and welding are employed to shape the materials according to design specifications.

- Assembly: The final assembly involves skilled technicians who ensure that all components fit together seamlessly, ready for delivery or further processes.

Why Choose Deep Mould as Your Metal Fabricator?

Choosing the right metal fabricator is crucial for the success of any project. Here’s why Deep Mould should be your go-to partner in metal fabrication:

Quality Assurance

At Deep Mould, we prioritize quality above all else. Our team follows stringent quality control measures throughout the fabrication process. Every project is thoroughly inspected to meet industry standards and client specifications.

Advanced Technologies

Innovation is at the heart of Deep Mould. We invest in cutting-edge technology, from automated machining processes to advanced software, to enhance efficiency and precision.

Experienced Team

Our team is composed of highly skilled professionals with years of experience in the metal fabrication industry. Their expertise ensures that each project is executed flawlessly, saving time and reducing costs for our clients.

Customer-Centric Approach

We believe in a collaborative approach. Our dedicated account managers work closely with clients, providing regular updates and adjusting plans as needed to ensure client satisfaction.

Industries We Serve

Deep Mould caters to a wide array of industries, including:

- Aerospace: Providing complex components that meet rigorous safety standards.

- Automotive: Manufacturing parts that are durable and lightweight.

- Construction: Fabricating structural components essential for building frameworks.

- Marine: Producing parts that withstand harsh environmental conditions.

- Energy: Developing components for various energy sectors, including renewable energy.

Custom Metal Fabrication Solutions

Every client has unique needs, which is why Deep Mould offers tailored metal fabrication solutions. We work closely with our clients to develop custom products that align with their specific requirements.

Prototype Development

For businesses looking to test new designs, our prototype development services enable iterative testing and refinement before full-scale production. This approach saves time and resources while ensuring product quality.

Bulk Production

Once designs are finalized, Deep Mould can facilitate bulk production, utilizing efficient processes to fulfill high volume orders without sacrificing quality.

Sustainability in Metal Fabrication

At Deep Mould, we recognize the importance of sustainability. We are committed to eco-friendly practices, including:

- Utilizing recycled materials where possible.

- Implementing energy-efficient processes to reduce our carbon footprint.

- Minimizing waste through strategic planning and material use.

Projects and Case Studies

Deep Mould has been involved in a variety of successful projects across different industries. Here, we present a few case studies that showcase our capabilities:

Aerospace Component Fabrication

We partnered with an aerospace company to develop lightweight structural components. Our use of high-strength materials ensured the parts met safety standards while providing weight savings, contributing to fuel efficiency.

Custom Fabrication for the Automotive Industry

For a prominent automotive manufacturer, we provided custom-chassis components, delivered on time and to exact specifications, improving their production efficiency.

Conclusion: Partnering with Deep Mould

In the fast-paced world of metal fabrication, Deep Mould remains a steadfast partner for businesses seeking quality, precision, and innovation. Our commitment to excellence and customer satisfaction is unwavering. For more information about our services, visit us at https://www.deepmould.net/ and discover how we can assist you with all your metal fabrication needs.