The Essential Guide to Cylinder Head Engine: Understanding and Maximizing Performance

The cylinder head engine is a pivotal part of any diesel engine, significantly influencing its overall performance, efficiency, and longevity. Whether you are a diesel engine enthusiast, a mechanic, or a business involved in diesel engine parts supply, understanding the intricacies of the cylinder head can provide valuable insights. This article aims to delve deep into the world of cylinder heads, exploring their functionality, types, maintenance tips, and how to choose the right one for your engine needs.

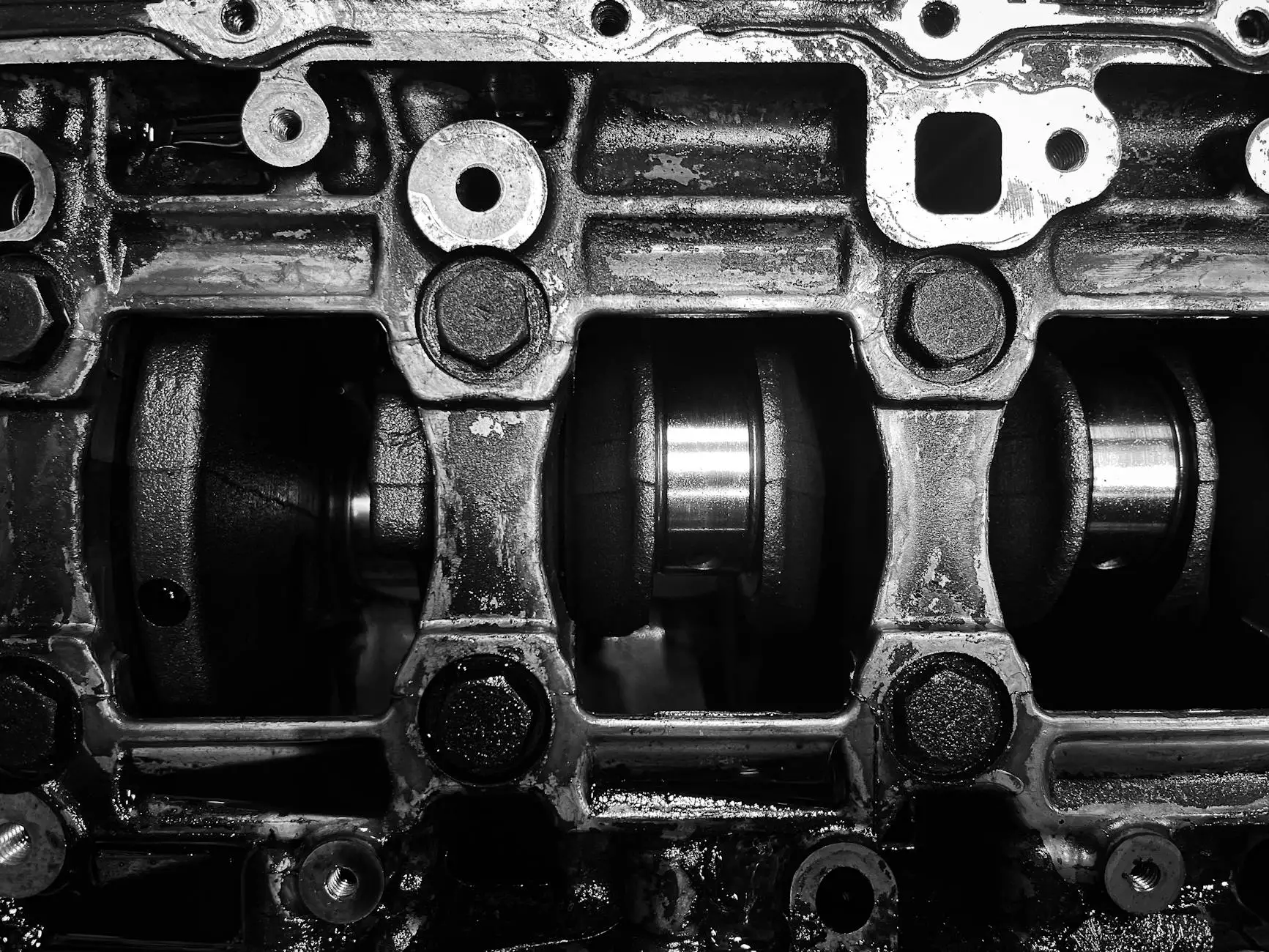

What is a Cylinder Head Engine?

The cylinder head engine is the component that sits atop the engine block, sealing the combustion chamber and housing critical components such as the valves, camshaft, and spark plugs (in gasoline engines). In diesel engines, it plays an equally vital role, serving as the interface between the intake and exhaust systems.

Key Functions of the Cylinder Head

- Sealing the Combustion Chamber: The cylinder head forms a crucial seal to prevent the escape of gases during combustion.

- Housing Valves: It contains the intake and exhaust valves which regulate airflow in and out of the cylinder.

- Cooling System: Cylinder heads have passages for coolant to help maintain optimum engine temperature.

- Facilitating Combustion: The design and configuration directly affect the combustion process, impacting efficiency and performance.

Types of Cylinder Heads

Understanding the different types of cylinder heads available is essential for anyone involved in the diesel engine parts business. There are primarily two types of cylinder heads:

1. Overhead Valve (OHV) Cylinder Heads

OHV cylinder heads feature valves located in the head itself, with pushrods to operate them. This design offers several benefits:

- Improved Performance: Enhanced airflow due to direct valve operation.

- Better Fuel Efficiency: More precise control over valve timing and lift.

- Compact Design: Smaller engine design while maintaining power output.

2. Overhead Cam (OHC) Cylinder Heads

These heads have the camshaft located in the head itself, resulting in more direct operation of the valves:

- Higher RPM Capability: Allows the engine to rev higher, delivering more power.

- Efficient Valve Timing: Better control over valve events improves combustion.

- Easier Maintenance: More straightforward access to components for repairs and adjustments.

Understanding the Importance of Cylinder Head Quality

When sourcing cylinder head engine parts, the quality of the cylinder head can make a tremendous difference in functionality and reliability. High-quality cylinder heads are engineered to withstand extreme pressures, temperatures, and environmental conditions. Here are some key aspects to consider:

1. Material Composition

Most cylinder heads are made from cast iron or aluminum. Each material has its advantages:

- Cast Iron: Durable and able to withstand high temperatures; often less expensive.

- Aluminum: Lightweight and provides better thermal conduction but may be more susceptible to heat damage.

2. Casting Quality

The casting process affects the strength and reliability of the cylinder head:

- Precision Casting: Ensures precise dimensions, leading to better fit and performance.

- Thin Walls: Improved weight reduction without compromising strength.

Common Cylinder Head Issues and Solutions

Understanding potential issues with cylinder heads is crucial for maintenance and repair. Here are some common problems:

1. Cracked Cylinder Head

Cracking often occurs due to overheating or thermal shock. Symptoms include:

- Coolant in the oil (milky appearance).

- Engine overheating.

- Loss of engine power.

Solution: Replace the cylinder head or utilize repairs such as welding if feasible.

2. Warped Cylinder Head

This issue is typically a result of overheating. You may notice:

- Excessive engine noise.

- Fluid leaks.

- Difficulty in maintaining necessary engine pressure.

Solution: A professional machinist can sometimes resurface the head, restoring proper functionality.

Choosing the Right Cylinder Head for Your Diesel Engine

When selecting a cylinder head, consider these key factors to ensure optimal performance:

1. Engine Specifications

Ensure the cylinder head matches the engine's make, model, and specifications. Compatibility is crucial for effective operation.

2. Purpose of Use

Is the engine used for standard driving, racing, or heavy-duty applications? Selecting a head designed for the intended use is vital for performance.

3. Manufacturer Reputation

Choose heads from reputable manufacturers known for quality and reliability. Research supplier reviews and seek recommendations.

4. Price vs. Quality

While budget considerations are essential, compromising on quality can lead to more expensive repairs. Invest in a head that offers longevity and performance.

Where to Find Quality Cylinder Head Engines

Finding a trusted source for your cylinder head engine needs is critical. At client-diesel.com, we prioritize high-quality spare parts for all your diesel engine requirements. With a wide range of products and a commitment to customer satisfaction, we ensure our clients have access to reliable engine components.

Conclusion

Understanding the complexities of the cylinder head engine is crucial for both enthusiasts and professionals. By recognizing its importance, types, common issues, and the right selection process, you can ensure optimal performance and longevity of your diesel engine. Always prioritize quality and compatibility when sourcing parts. Whether you're maintaining an engine for personal use or overseeing a commercial operation, knowledge is key.

Your Next Steps

If you're ready to enhance your engine performance, explore our extensive catalog at client-diesel.com today and find the perfect cylinder head engine for your needs!